Here I go again with another late bloomer endeavor- this time to start my own Die cast Toy collection! Being part of my never ending "bucket list" of things I SHOULD do, there's no better time to do it but NOW...I'm relatively new to collecting stuff in general but, as with other items on my list, it has always been driven by activities I wanted to do as a child general which I never got to do for one reason or another. As usual, it all begins with my usual research:

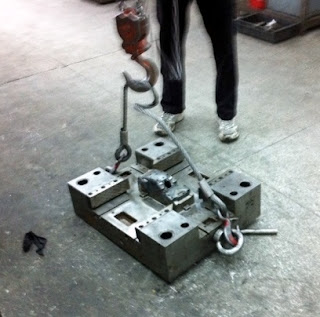

Diecast (die cast or die-cast) in general refers to a

metal casting process forcing

molten metal, under great pressure, into a die or form

mold cavity to give it a specific shape. Specifically,

Die-cast toys are scaled down models, usually of automobiles, that are often made via casting.

Though expensive to set up, the process can mass produce castings at relatively low cost per piece. The key to the process mainly accounting for the production expense is what is called the "form" (tooling) where the delicate balance between the fine texture of the metal and the precision of the die is combined to create very detailed scaled down model pieces- when desired.

The building material actually is NOT the same as steel or iron but is called

"Zamak" (or Mazak in the UK), which is an alloy of

zinc with small quantities of

aluminium and

copper combined eventually with some plastic parts to add more details. Older technology used in other types of metal toys may be confused with die cast such as

Cast Iron (used in the early to mid 1900's) and

Stamped metal (post war era).

These produced rather crude toys by today's standards but were actually fore runners of today's modern toys which were carried by prominent toy companies during those periods (Cast iron:

Arcade,

Wilkins, Hubley, Kenton, etc,; stamped steel:

Tonka, Buddy L,

ERTL, etc.)

With the current die cast technology giving toy makers more flexibility to be more creative and precise, the trend for greater detail continues with manufacturers finding more innovative ways to keep costs down and variety up. While the industry itself continuous to flourish, this has not come without challenges. Beginning 2005,

zinc prices began to rise substantially on the global market resulting to a steady rise in the shelf price of die cast toys and models these past several years coupled by increase in overseas labor and lower production quantities.

No comments:

Post a Comment